The custom-shape suspended platform is a kind of non-standard suspended platform with special specifications and it is tailored to meet the requirements on the construction of irregular buildings. The platform features light weight, high utility, high security, and reasonable price. Its main part can be freely moved and restructured, making it convenient and efficient to complete the construction and maintenance work of irregular buildings.

New Age believes in customised solutions for rope suspended platforms to cater to its clients with higher safety features. L-type (90 degree), C-Shape, Curve-Shape, W-Shape, square shape, round shape, multiple front extension platforms, front extension (fixed/ folding) and multiple modifications in suspension mechanism/ parapet clamping/ wall brackets are highly appreciated and accepted by the trend setters in construction segment.

Rope suspended platform (RSP) which is commonly known as Gondola (or cradle, or RSP) is electrically-operated, temporarily-installed suspended access equipment which is a suspended manned facility for work at heights by relying on a movable platform driven by motor, designed to suspend along the vertical surface of building by steel wire ropes through the suspension mechanism placed at the top of building. The suspended access equipment is featured in strong construction adaptability, higher construction height, less occupation of land, high efficiency, etc.

RSPs are now widely used in India for working at height for installing billboard or windows, window cleaning, external renovation, plastering, painting etc. This is an easy-to-use and efficient solution for vertical transport. Utilising decade of engineering experience, the company developed a modular system that makes it easy to quickly adjust the platform’s dimensions.

Earlier, suspended platforms meant a 7.5-metre straight structure design but now New Age has changed the definition. The company developed different designs of RSP in our factory at Rajkot. Machines were installed at different tall structures and received remarkable feedbacks on safety, easiness and quality. When designing and fabricating suspended platforms, the focus is on quality and reliability in the first place. First class materials and components guarantee long life cycles, outstanding durability and wear resistance. The company always believes in higher safety, faster work and higher productivity.

Customisation in rope suspended platforms:

L-Shape (90 degree) RSP: 12 nos. of L-shape RSP were operated at L&T-GRAND CENTRAL, Navi Mumbai site by his facade contractors. The working of straight RSP was failure due to the 900-MM curve shape reeds on multiple locations on external walls. Even front overhang was also extended up to 2.5 metre to cover reeds areas.

Other Sites: Bangalore, Pune, Ideal-Kolkata, TATA-Bangalore.

Square-shape RSP: This is a unique design of suspended platform proposed first time for BG SHRKE site, Mumbai for duct areas. Later, the same design accepted by L&T-Bombay Dyeing, L&T-Minerva and Marathon Monte South for lift-shaft areas. This machine is easily accessible for all four walls of shaft. Now, the people can work easily at all four walls at the same time without any shifting of machine. This machine is designed to reduce time and shifting cost. This concept is much faster than any other arrangements and considered a revolution in its industry. Bamboos, H-frames or any other standard RSP cannot place the importance of square-shape gondolas.

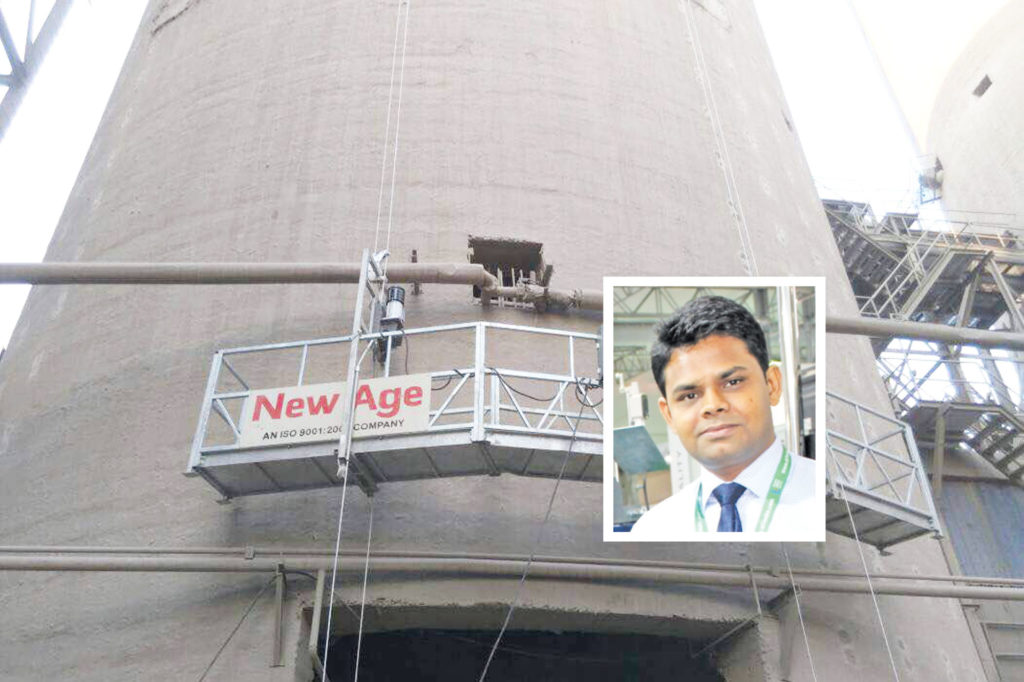

Curve-shape RSP: This type of machine is specially used at Chimneys, Silos. This RSP requires for repainting, painting, cleaning and maintaining on the round walls of Silos.

Sites: JK Cement – Karnataka, JK Laxmi Cement Ltd- Rajasthan, Chambal Fertilizer Chemical Ltd, Kota.

10 MTR RSP: Normally, a 7.5-metre standard RSP is used at construction sites. Now, think about a dead wall with width of 10-11 metre and building height is approximately 150 metre. It means shifting requires for covering width of 11 metre area. In such scenario, New Age introduced a 10-metre length of RSP to cover dead wall work in a single time without any shifting. This machine was designed with all advance safety devices. It reduced a big time gap and cost as well.

This machine was proposed first time at Lodha New Cuffe Parade site to its painting contractors. Later machines were used successfully at Wadhwa-54, Lodha Amara, Mumbai and some other sites.

Front Extension RSP: There are two types of front extensions in platforms. The first one is fixed extension and another is flexible mechanism. Both the mechanisms are very useful for working at difficult sites and specially got very positive response for repainting works at old residential societies. The company changed the dimensions of front extension as customer required, site to site and helped them in their project completion.

Site: Emami City- Kolkata, Happyville & Waterfront projects- W.B., L&T-Vapi, Bharatiya City-Bangalore and so many sites in different cities.

Round-shape RSP: The concept of round-shape platform was first introduced by New Age in India for chimneys’ internal works. The company developed and installed a round-shaped platform at Neyveli, Tamil Nadu site for 300-metre working height, 3-tonne loading capacity and 6.8-metre diameter.

Authored by:

Santosh Chaurasia

General Manager – Sales & Marketing

New Age Construction Equipment Engg. Co

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.